Aerogel vs. Rock Wool

Key Differences Engineers Should Know

Both aerogel and rock wool are mainstream thermal insulation materials in industrial fields, but they differ significantly in core performance, application scenarios, and long-term benefits. These differences directly affect the design, energy consumption, and operation and maintenance costs of engineering insulation systems. For engineers, accurately grasping the following key differences is a core prerequisite for scientific material selection.

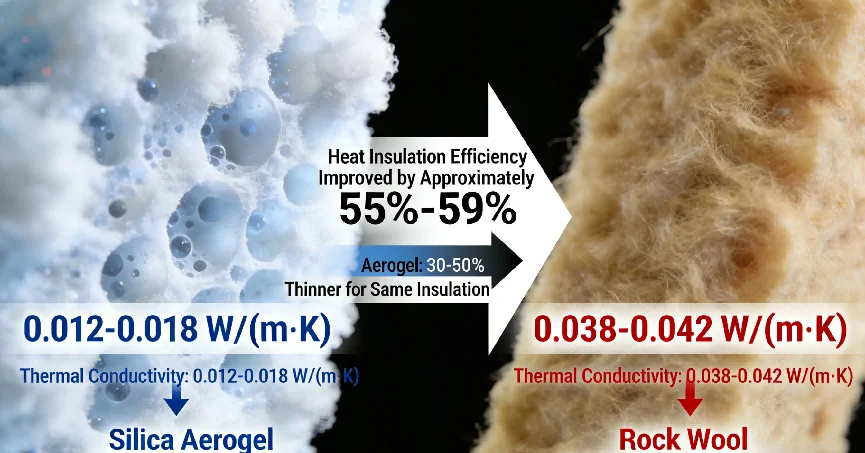

1. Thermal Insulation Performance: Aerogel Has an Overwhelming Advantage

Thermal insulation performance is the core indicator of industrial insulation materials, evaluated by thermal conductivity (λ): the thermal conductivity of aerogel is as low as 0.012-0.018 W/(m·K), while that of rock wool is usually 0.038-0.042 W/(m·K). This means that to achieve the same thermal insulation effect, the laying thickness of aerogel is only 1/3 to 1/2 of that of rock wool, which can greatly save installation space. It is especially suitable for industrial plant scenarios with dense pipelines and limited space.

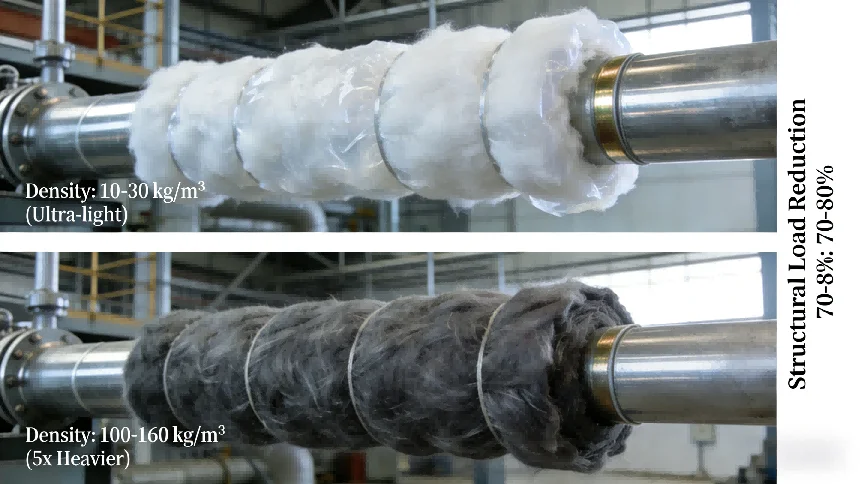

2. Density and Structural Load: Aerogel Is More Lightweight

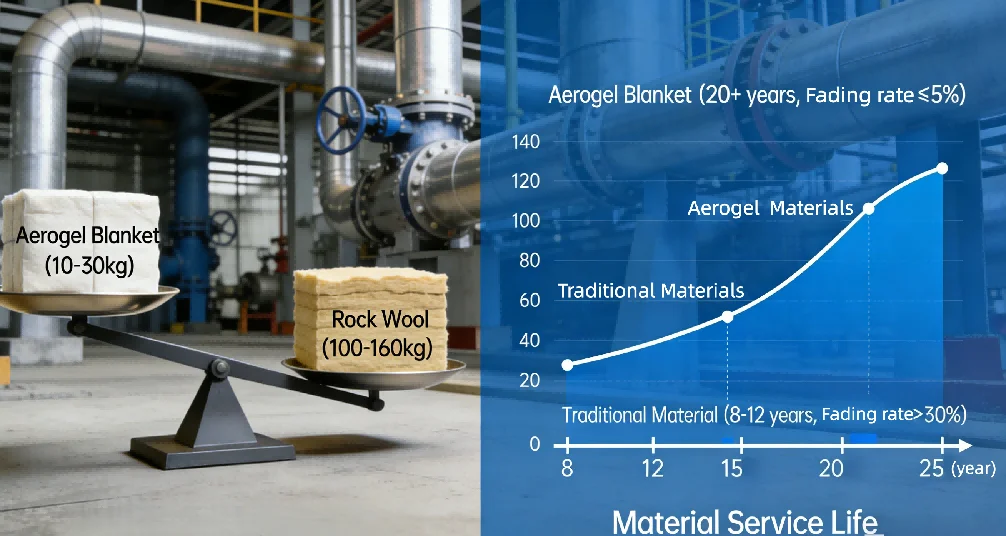

The bulk density of aerogel is only 10-30 kg/m³, making it an ultra-light material; the bulk density of rock wool is 100-160 kg/m³, more than 5 times that of aerogel. For engineers, lightweight aerogel can significantly reduce the bearing load of building envelopes and pipeline supports, reducing structural reinforcement costs. It is especially suitable for projects sensitive to load, such as old plant renovation and high-altitude pipeline insulation.

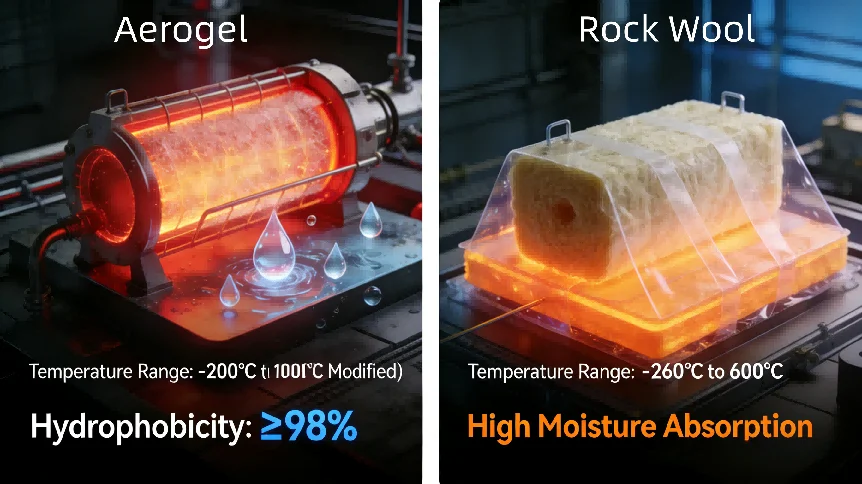

3. Temperature Resistance and Environmental Adaptability: Each Has Its Adaptable Range

The temperature resistance range directly determines the application scenario of the material: ordinary aerogel has a temperature resistance range of -200℃ to 650℃, and the high-temperature modified type can exceed 1000℃, adapting to complex high and low temperature working conditions; the conventional temperature resistance range of rock wool is -260℃ to 600℃. Although it has excellent low-temperature adaptability, it is prone to pulverization and rapid performance attenuation at high temperatures. In addition, aerogel has super hydrophobic properties (hydrophobicity ≥ 98%), which can avoid the decline of thermal insulation performance in humid environments; while rock wool has strong moisture absorption and requires additional waterproof wrapping, increasing engineering complexity.

4. Service Life and Operation & Maintenance Costs: Aerogel Is More Long-Lasting

Aerogel has strong chemical stability, is not easy to age or pulverize, has a service life of more than 20 years, and does not require frequent replacement and maintenance; rock wool is prone to aging and falling off in long-term high-temperature and humid environments, with a service life of usually 8-12 years, requiring additional replacement and construction costs later. From the perspective of life-cycle cost, although aerogel has a higher initial purchase price, it can achieve long-term benefits by reducing energy consumption and operation and maintenance costs.

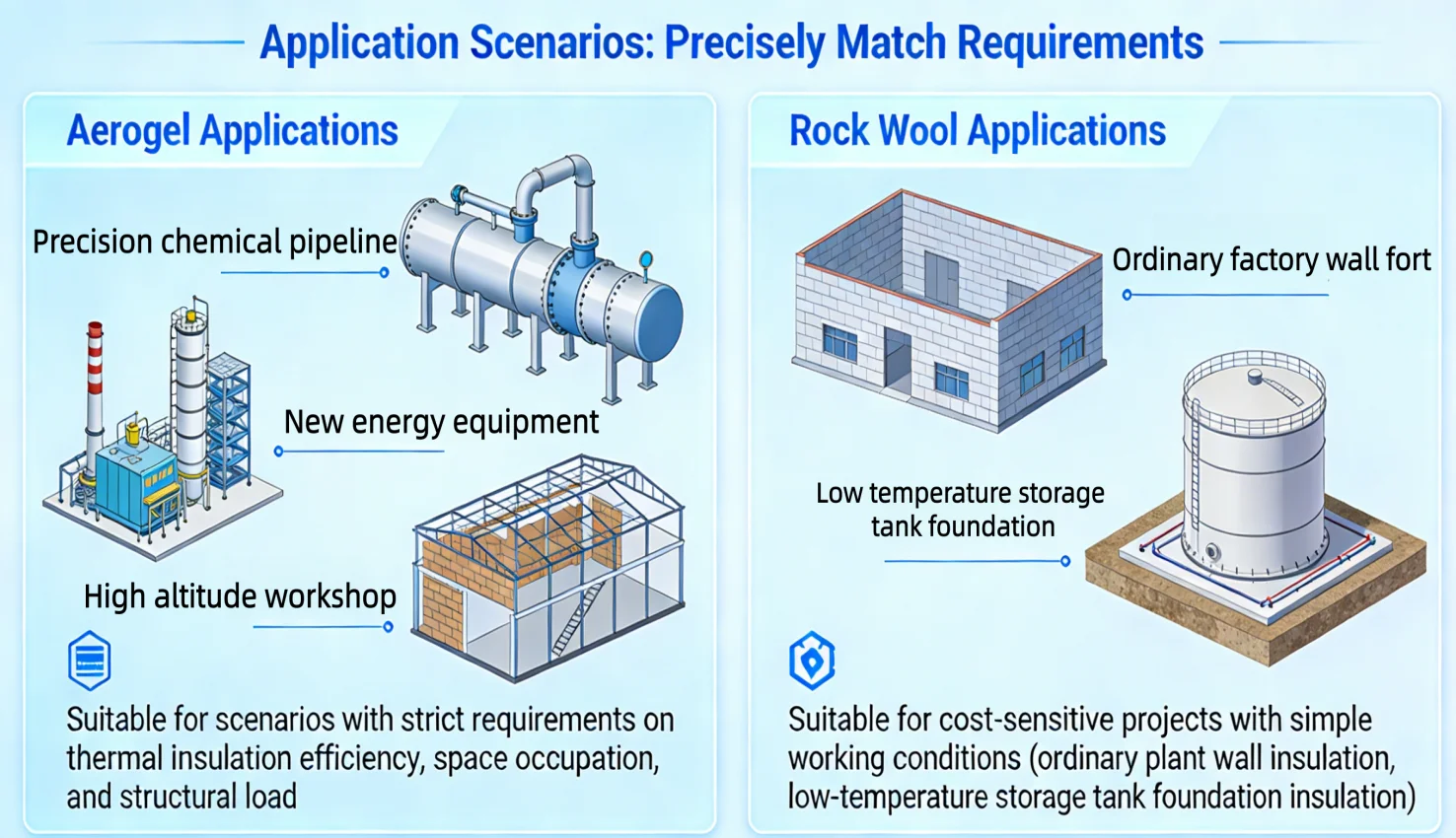

5. Application Scenarios: Precisely Match Requirements

Engineers need to select materials according to the core needs of the project: aerogel is suitable for scenarios with strict requirements on thermal insulation efficiency, space occupation, and structural load, such as precision chemical pipelines, new energy equipment, and high-altitude plant envelopes; rock wool is suitable for projects sensitive to cost and with simple working conditions (such as ordinary plant wall insulation and low-temperature storage tank foundation insulation), and becomes a common choice for basic insulation by virtue of its cost-effectiveness.

In summary, aerogel and rock wool are not a “competition between superiority and inferiority” but a “choice of adaptation”. Engineers need to reasonably select materials based on the project’s thermal insulation requirements, space conditions, load constraints, and life-cycle cost to realize the efficient, economical and stable operation of the insulation system.